The 165 kg payload of the Fanuc R-2000iC/165FH hollow arm robot makes it the perfect choice for any operation requiring process cables, such as material handling or spot welding. Due to broad open maintenance holes and simple access to the integrated process cables for independent exchange, its hollow arm design enables totally internal cable routing.

Comparing the installation space to the R-2000iC models, it was reduced by 23%. Due to the integrated process cable routing’s seamless elimination of interference contours from the cables during offline simulation, its compact shape and design make integration incredibly simple.

Press the “Contact Us” button below to have our RobotWorld engineering team reach out to you or give us a call at 313-242-0505 today. We are a premier Fanuc Authorized Integrator located in Southeastern Michigan with a 100,000 square foot facility to serve all of your integration needs!

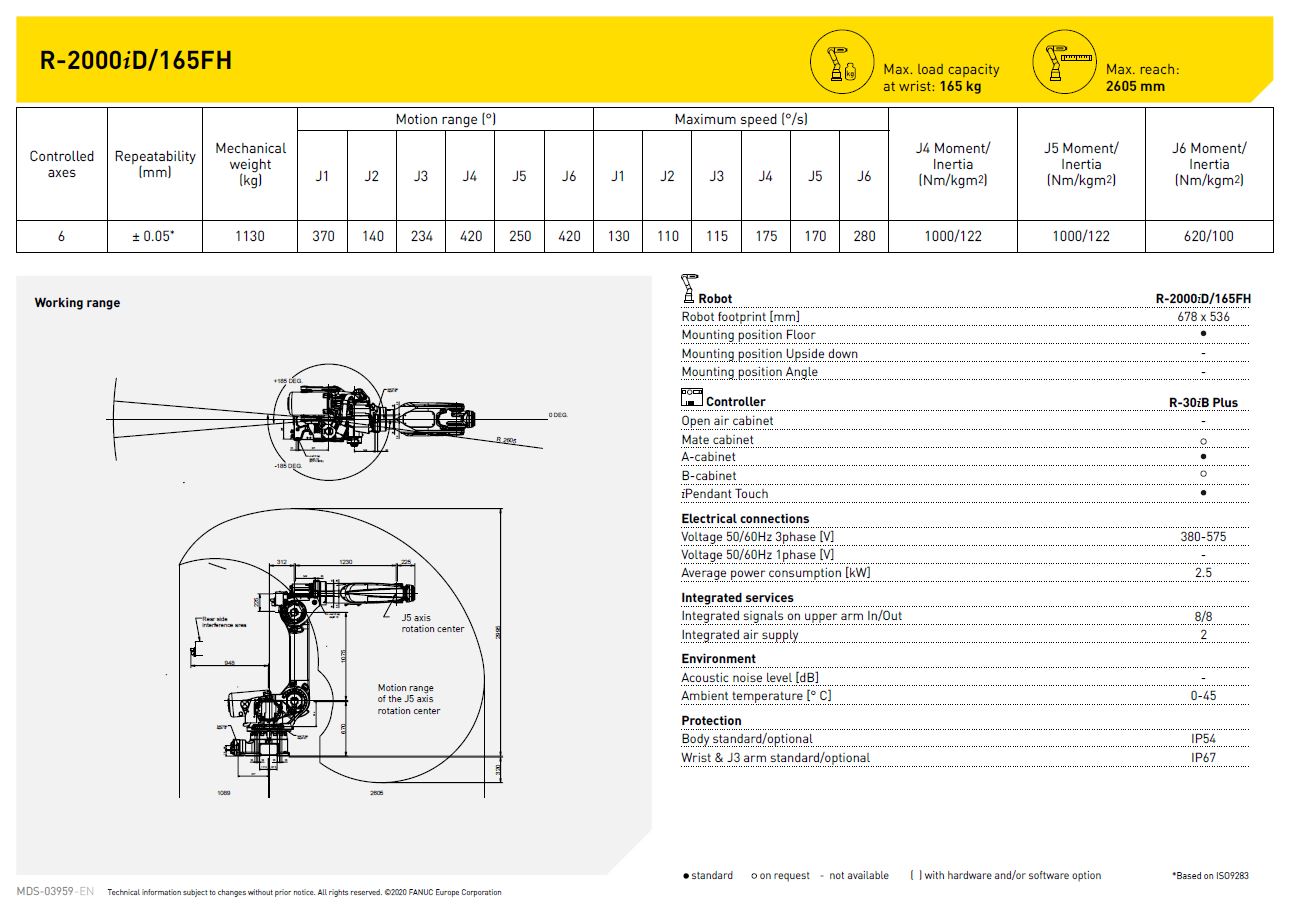

Specifications

| Axes: | 6 |

| Payload: | 165 kg |

| H-Reach: | 2605 mm |

| Repeatability: | ±0.05 mm |

| Robot Mass: | 1130 kg |

| Controller: | R30iB Plus |

| Mounting: | Floor |

Motion Range

| J1: | 370° |

| J2: | 140° |

| J3: | 234° |

| J4: | 420° |

| J5: | 250° |

| J6: | 420° |

Maximum Speed

| J1: | 130 |

| J2: | 110 |

| J3: | 115 |

| J4: | 175 |

| J5: | 170 |

| J6: | 280 |