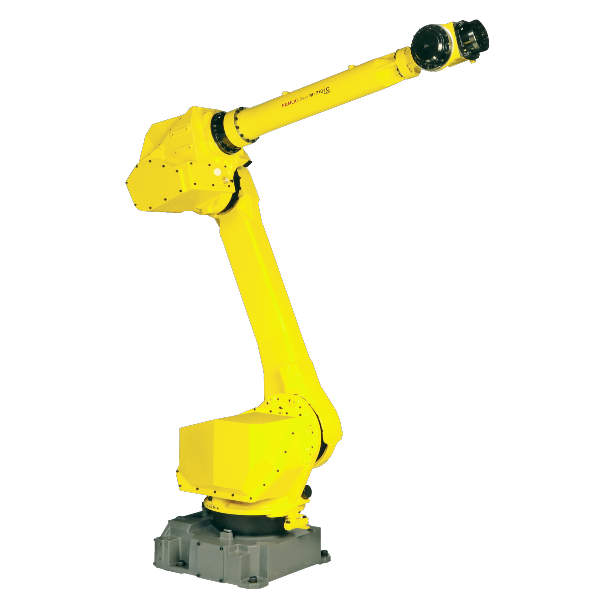

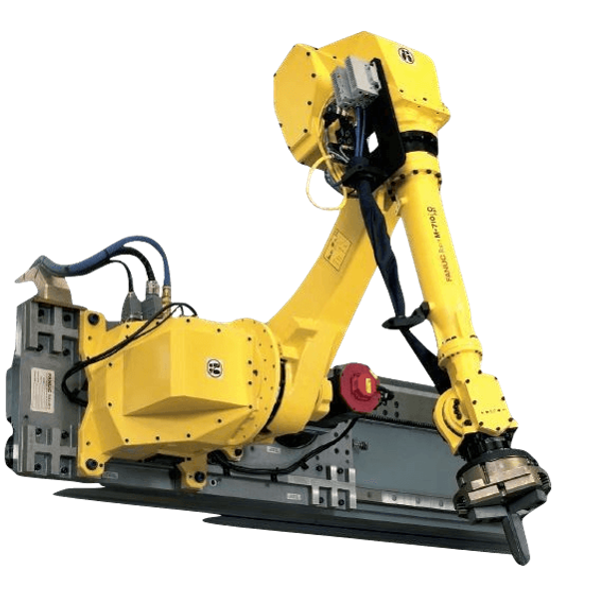

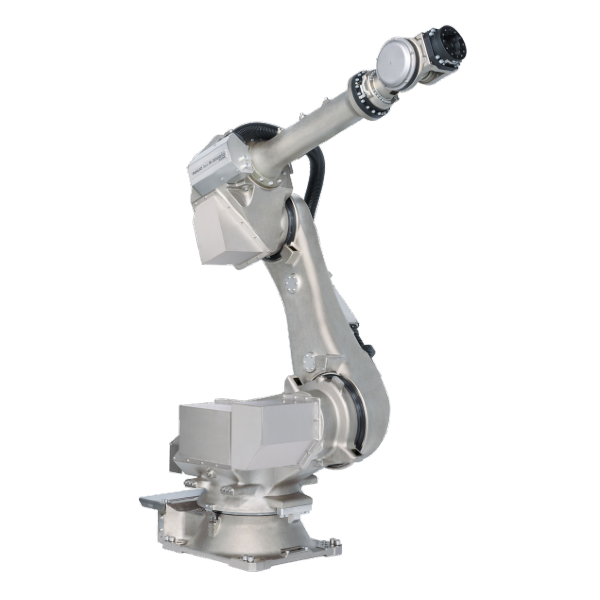

One of the first images that come to mind when people think of industrial robots is robotic assembly. Heavy-duty six axis robots are used in the automotive industry, which was essentially the first to standardize robotic automation, to increase capacity and enhance manufacturing processes.

As we see more and more opportunities for high-speed robotic assembly of small intricate parts, assembly line robots today go far beyond automotive. Robotic assembly line processes offer the speed and accuracy manufacturers need without compromising on quality or accuracy. Because assembly line robots can easily perform multiple value-added processes, eliminating the need for costly fixed automation, manufacturers can easily optimize workflow, increase capacity, and produce a wider range of products.

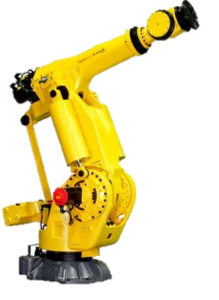

FANUC manufactures a wide range of highly dependable assembly robots that are repeatable, compact, and fast. They offer robots and the intelligent features needed to allow RobotWorld to assist in keeping your production goals on track, from 5 to 6 axis articulated robots to 3-6 axis delta robots to SCARA SR Series and Collaborative Robots.

Integrated iRVision from FANUC

Robotic vision enables the robot to “see” and retrieve a component from a conveyor or tray, eliminating the need for extensive programming. iRVision can help with inspection, gauging, detection, and error proofing in addition to part location. Contact our RobotWorld engineering team with with your production needs and allow us to provide a solution!